PADI Gas Blender Course

More and more people are diving with enriched air and this means Padi Gas Blender course and the demand for enriched air fills is also increase. However, there needs to be someone qualified to administer these fills to meet this demand. This is where the DSAT Gas Blender course comes in. It can result in one of two certifications: DSAT PADI Gas Blender Nitrox or DSAT PADI Trimix Blender.

The Gas Blender course will train you as a qualified gas blender, allowing you to provide gas mixes to appropriately certified consumers. You’ll learn the physical properties of oxygen and helium its associated hazards, handling requirements and what cleaning equipment is necessary. Finally, you will learn the five methods of obtaining the desired enriched air nitrox mix and the various methods used to obtain proper helium mixes.

To be a PADI Gas Blender you need to be:

- PADI Enriched Air Diver certification (or qualifying certification from another organization)

- Minimum age: 18 years old

Ready to learn the deepest depths to the shallows of our air we breathe? Ascend to our level at EASY DIVERS to sign up.

Nitrox Made Easy: Which Nitrox system should I buy?

When deciding which Nitrox System to purchase there are a couple things you might take into consideration to help you make the best decision:

You can use this spreadsheet to understand the types of costs associated with each of the different methods to make Nitrox. Nitrox Cost Breakdown Spreadhseet Here is an additional spreadsheet to help you understand what it costs to fill a SCUBA tank at your shop. Tank Fill Cost Spreadsheet Easy Divers Services has an inexpensive downloadable Gas Blender Manual that has a wealth of information about Nitrox. There are three major ways out there to make Nitrox. They are:

There are advantages and disadvantages to each of the systems, here’s a quick run-down of their strengths and weaknesses: |

|

Nitrox Partial Pressure Blending:

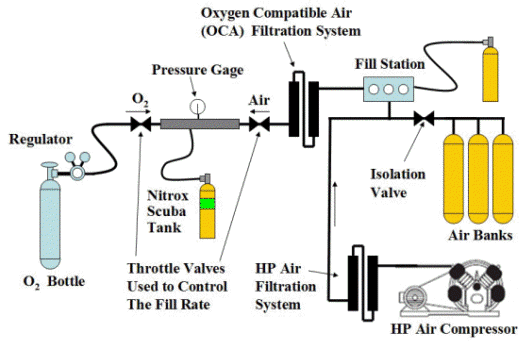

Mixes pure oxygen directly into an empty and oxygen clean certified SCUBA tank, then topped off with with Oxygen Compatible Air (OCA) from banks to create desired oxygen mixture. Depending on the complexity of the blending station, you will spend a couple thousand dollars on the mixing panel and additional filtration system. Bottled oxygen needs to be obtained from your local gas Gas Distributor.

Advantages

- Lowest initial start-up cost

- Able to mix any mixed gas percentage

Disadvantages

- Very tedious process – Substantial amount of labour, generally 20-30 min, to fill each SCUBA tank.

- SCUBA tanks and fill system need to be Oxygen Clean Certified – more expensive VIP process.

- Potentially dangerous if oil has been inadvertently admitted to SCUBA tank (diesel effect resulting in explosion)

- Unable to use all Oxygen in O2 Tank unless you have a Booster Pump. Usually send O2 tank back to Gas Distributor with ~400 psi.

- Accuracy of Nitrox mix is dependant on the proficiency of the person operating the fill station.

- Need to have readily available supply of Oxygen

Greg McLaughlin from Jack’s Diving Locker in Kailua-Kona, Hawaii, wrote a great partial pressure blending calculator for the iphone that will also work on your web browser. It works best on Firefox or Safari. http://iphone.somemore.com/mixer/

More information about the calculator is available at: http://iphone.somemore.com

Nitrogen Separating Membrane:

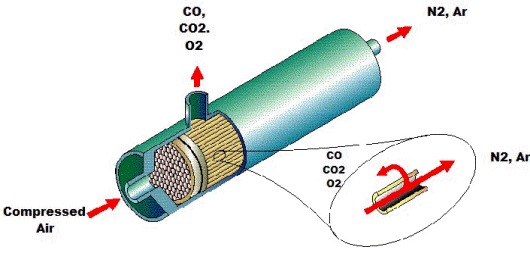

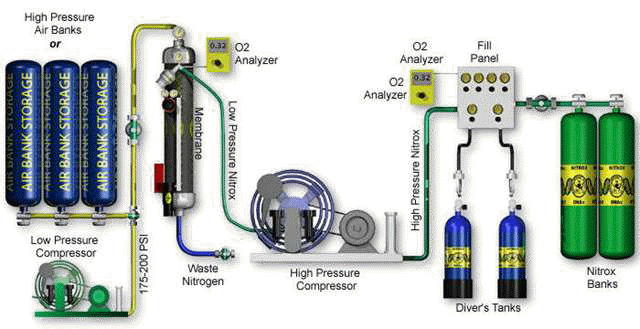

This technology was initially developed by the welding industry to generate Nitrogen. It uses a low pressure air source (or a high pressure air source regulated to low pressure) to force heated air through a special membrane system. There are two outlets from the membrane: one for the nitrogen vent, and one for the permeate (enriched Oxygen mixture) that goes into your high pressure air compressor. There are a couple different variations on this design. The oxygen content is controlled by either adjusting the input pressure to the membrane or adjusting the nitrogen vent. The membrane is unstable initially until it reaches operating temperature (~30 min). Adjustments to the membrane input pressure or nitrogen vent typically take about a minute before their affects stabilize at the oxygen sensor at the inlet to the HP air compressor. The outlet of HP air compressor is either sent directly into SCUBA tanks or a Nitrox Bank. More information about nitrogen separating membranes is available at AirLiquide, and Air Products.

Advantages

- Requires no bottled oxygen, independence from oxygen distributors.

- Can safely make Nitrox up to 40%

- Scuba tanks and fill system do not need to be oxygen clean.

Disadvantages

- Expensive initial procurement cost – typically on the order of $15-20K for a system capable of delivering 36% Nitrox at 15CFM

- System is slow to start up and can be frustrating to operate – difficult to dial in desired oxygen mixture. The heated air fed to the membrane causes the chemical reaction in the oxygen sensor to speed up, significantly throwing off oxygen analyser calibration.

- Additional costs (electricity/maintenance) associated with running low pressure air compressor to supply air to membrane.

- If HP air banks are used to provide input air pressure to membrane – there is an enormous amount of wasted HP air and associated HP compressor electricity and wear.

- If filters are not frequently changed, membrane can get clogged with dirt particles, requiring its replacement – expensive!

- Membrane is fragile and can be damaged due to carelessness, if over pressurized or not properly heated (making the tubes brittle), you can easily burst the small tubes inside, requiring the membrane to be replaced – expensive!

- Replacement membranes are expensive! If system the is equipped with a LP compressor, a replacement membrane represents about half the cost of the system. If the system uses a HP to LP regulator, the replacement membrane represents about two third’s the cost of the system. A replacement 6 foot membrane (used with 15CFM compressors) costs $8K.

- System should be constantly monitored during operation.

- Usually the highest cost per Nitrox SCUBA Tank.

Nitrox Panel Membrane System – Coltri Sub

- Simple complete “Turnkey” operation

- Adjust the regulated input to supply the desired oxygen %

- Only 1-hour operator training required

- 2 hour average installation

- No compressor modifications

- Reliable mix accurate to one tenth of 1%

- Up to 20 year life

- Produces from 21% to 40% oxygen

- Unlimited continuous on-site production

- Low pressure or high pressure supply

- No size or flow limits

- Banked, hot fills, or continuous nitrox output

- Ideal for remote sites and live-aboards

- Compact and lightweight

- Trimix systems available

- Oxygen levels of up to 40%

- High volume output means no waiting for fills

- Easy maintenance (1 inexpensive filter change each quarter)

- Operates on Grade D or E Air

- Use your existing oil lubricated compressor (some compressors may not be suitable for nitrox use)

This Nitrox System uses semi permeable membranes to produce oxygen rich air (nitrox). The nitrox, at up to 40% oxygen, can then be compressed with an oil lubricated high-pressure compressor into scuba bottles or storage tanks for later use or with a low-pressure compressor for immediate delivery to divers.

The “New & Improved” membrane system is up to 20% more efficient and easier to use. The system requires an air source to supply air to the membrane for separation. This air source (supply air) can be from high-pressure storage tanks or from a low-pressure compressor.

First, the supply air pressure must be reduced to 80-300 PSI for use in the membrane. A regulator is used to adjust the input pressure and volume of nitrox to be made. After the regulator the air travels through filtration to ensure a proper air quality that will not damage or plug the membrane fibres. After the filtration the air is heated to a stable temperature that is constant and optimal for the membrane permeation. This temperature is about 110 degrees F. After the heater the air enters the membrane.

The membrane is made up of thousands of hollow fibres. Oxygen permeates faster than nitrogen through these fibres. At the nitrogen outlet there is a fixed orifice that will allow the right amount of nitrogen to escape at maximum output to produce about 43% oxygen at the permeate outlet (oxygen rich gas). The permeate exits the membrane into a static mixing tube that allows ambient air to mix with permeate. The gas mixture is then analysed with an in-line sensor before delivery to the compressor for compression.

As the operator increases the input pressure on the regulator, the volume of nitrox produced is increased as well as the oxygen % of the total gas mix. Decreasing input pressure will lower the nitrox oxygen % mix.

This system requires a separate LOW PRESSURE COMPRESSOR or a LOW PRESSURE STORAGE TANK to operate the membrane.

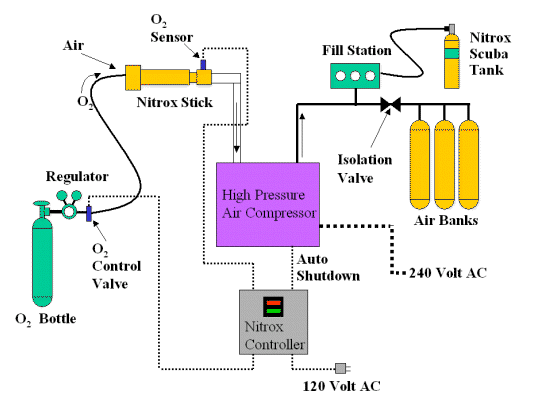

Continuous Nitrox Gas Blending with Nitrox Stik:

The Nitrox Stik continuous gas blender uses O2 tanks and a patented blending “Stik†to homogeneously mix air and pure oxygen at the inlet of a high-pressure air compressor. Placing the system on service involves isolating the system’s air storage bank, bleeding all the air out of the lines on the discharge side of the compressor (this reduces the time it takes to purge the air and replace it with Nitrox), and then while the compressor is running, placing the oxygen tank on service and throttling the oxygen supply to achieve the desired oxygen concentration.

Continue bleeding the discharge of the air compressor until the system is purged and the oxygen analyser monitoring the outlet of the compressor indicates the desired oxygen concentration. The air compressor, associated filters and air lines have now all been purged and he outlet of HP air compressor is either sent directly into SCUBA tanks or a Nitrox Bank. It typically takes between 5-10 minutes to place the system on service and start filling Nitrox SCUBA Tanks.

Advantages

- Moderate initial procurement cost – $2300 for the Nitrox Stik and an additional $2700-$3200 (depending on size of HP compressor) for the Nitrox Controller.

- Can Safely make Nitrox up to 40%.

- Scuba tanks and fill system do not need to be oxygen clean.

- Nitrox Controller allows operator to attend to other matters while filling Nitrox Tanks, reduces labor costs, increases accuracy of Nitrox Mix, and has additional safety features.

- Usually lowest cost per Nitrox SCUBA Tank by far when considering oxygen, labor and operating costs.

Disadvantages

- System should be constantly monitored during operation (unless Nitrox Controller is installed).

- Need to have readily available supply of Oxygen.

When taking everything into account, the Nitrox Stik with the Nitrox Controller usually makes the most sense.

“Dial a Narc”

For some, the title “Dial a Narc” may conjure up visions of an anti drug SWAT team kicking in a door. However, for deep divers, it is a phrase commonly used when discussing breathing gas mixes that include helium. It means that by simply replacing some of the narcotic gas “nitrogen” with the physically inert gas “helium,” a diver can actually predict and control the level of nitrogen narcosis for any dive.

Imagine diving a pristine wreck with her upper decks sitting at 200 fsw. Some divers would make this dive on air, and, yes, there would be measurable narcosis. This narcosis could range from a reduced level of function to total debilitation. Much would depend on the individual’s physiology and the diving conditions. Dark, cold, CO2 retention, fitness level, and physical exertion all play a role in the level of nitrogen narcosis.

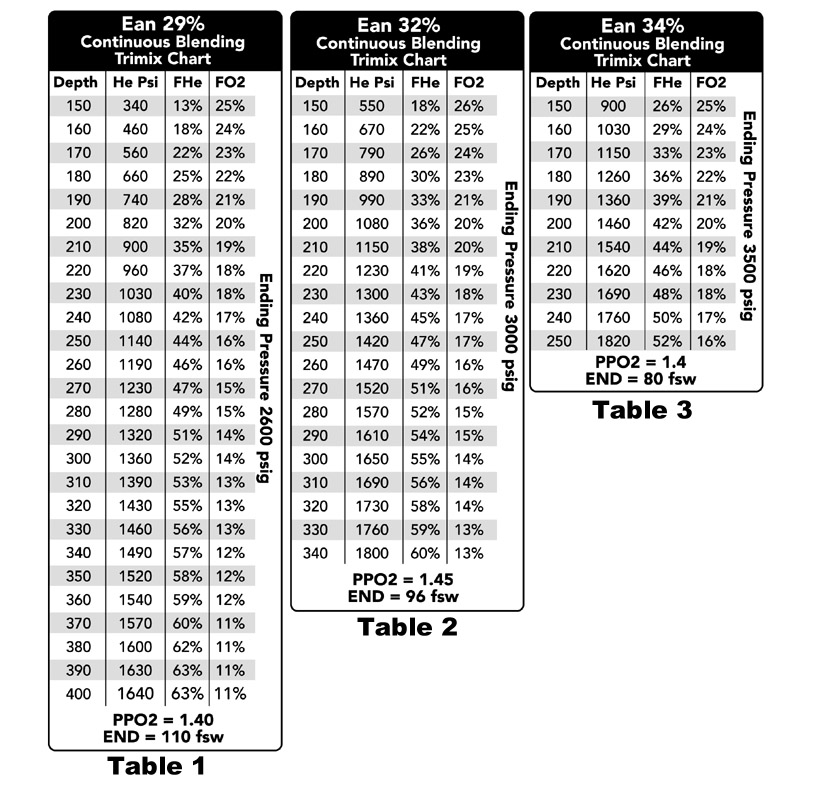

Consider the same 200 fsw dive with some of the nitrogen replaced by helium. According to the accompanying tables, by transfilling 1080-psi of helium into a 3000-psi cylinder, then topping up the remaining 1920 psi with a 32% nitrox mix, the final mix is 20% oxygen, 44% nitrogen, and 36% helium. This is a mix with enough oxygen content to sustain life at the surface, which means that no travel gas is required. It also has a nitrogen narcosis level that is equivalent to an air dive to 96 fsw and the PPO2 is 1.45.

(See Table 2.)

Just think, now a diver can explore that deep wreck with a totally clear head. While this is exciting, it is important to remember not to dive mixed gas without the proper training. Decompression requirements and equipment configuration, among other things, are quite different from diving air.

What about mixing gases, Oxygen Helium Nitrogen?

Many blenders find that helium mixes are actually easier to mix than enriched air nitrox. Helium mixes are generally both helium and oxygen (Heliox), or a helium, oxygen and nitrogen mix (Trimix). Although mixing the three gases separately will work, blenders usually take advantage of available combinations, such as air and nitrox, to mix with helium.

Mixing helium with air (Heliair) or helium with nitrox (Helitrox) is accomplished by partial pressure filling a cylinder with pure helium, then topping up to the final pressure with air or nitrox.

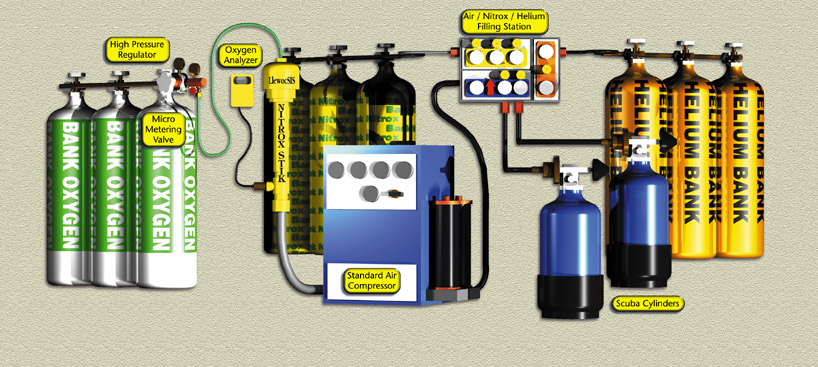

Introducing a “Nitrox Stik” into a standard scuba compressor can turn an otherwise simple air only unit into a complete gas blending system. Illustrated below is a “Nitrox Stik” used to either fill nitrox straight into scuba cylinders, fill nitrox storage banks for later use, or on top of helium to create helitrox. The only pieces added to the system are the “Nitrox Stik” system, oxygen analyser, banked oxygen, and banked helium.

To use these charts:

1. Find the desired maximum depth.

2. Choose the desired ending scuba cylinder pressure.

Table 1 = 2600

Table 2 = 3000

Table 3 = 3500

3. Intersect the desired depth with the helium psi required on the table chosen. Fill an empty scuba cylinder with the required psi of helium.

4. Top off the scuba cylinder to the ending pressure on the chart chosen with the required percentage of nitrox.

Table 1 = 29%

Table 2 = 32%

Table 3 = 34%

5. Analyse, then readjust.

Above: ADM has provided these easy to use helitrox-blending tables. Each table uses a different nitrox percentage, ending final pressure, PPO2 and END.

- Table 1. Ean 29% is placed on top pre-filled helium to an ending pressure of 2600 psi.

- Table 2. Ean 32% is placed on top pre-filled helium to an ending pressure of 3000 psi.

- Table 3. Ean 34% is placed on top of pre-filled helium to an ending pressure of 3500 psi.

The PPO2 and END, indicated on the bottom of each table, has been calculated +/- 0.03 PPO2 or +/- 3 fsw END for each depth and mix.

To do this, the diver will need a partial pressure fill whip, with a 580 CGA fitting for the helium cylinder on one end and an accurate pressure gauge, micro metering valve and SCUBA cylinder (either yoke or DIN) on the other end. Additionally, plan on either obtaining a booster pump for the helium or cascading the cylinders to be able to utilize the lower cylinder pressures. For Helitrox, an accurate method of delivering nitrox is required.

By far the simplest, safest, and least expensive way to mix gases is the continuous blending system called the “Nitrox Stik.” The “Stik” mixes low pressure oxygen with the compressors’ intake air through a patented static mixer. It creates a homogeneous gas mix, without restricting the flow to the compressor. The result is an inherently accurate nitrox blending system that makes nitrox as easy as pumping air. Technically, because of the different compressabilities of the gases, “real” gas laws should be used. Although, the reality is that gas blenders treat the gases as if they behave the same when compressed. This is called “ideal” gas laws. With experience, some blenders develop an intuitive “fudge factor” to take into account the differences, but for most blenders, just following the “recipe” will get remarkably accurate mixes.

To mix Helitrox, first consider the maximum depth of the dive. Decide the desired equivalent narcosis depth and the maximum PPO2. Enter the tables at the desired depth, and note the amount of helium to trans-fill into a cylinder. Top up the cylinder with the indicated nitrox mix to its ending pressure, and analyze the oxygen content.

For example, if the maximum depth of the dive is 280 fsw, note on the EAN29 table (table 1) that by transfilling 1280 psi of helium into an empty cylinder, then topping up to 2600 psi with EAN29, the final mix will have 15% O2, 36% N2, and 49% HE. The PPO2 for this mix, at our maximum depth of 280 fsw, is 1.4 and the EAD is 110 fsw.

Is it really this simple? Yes, but there are several points to keep in mind.

1) With one strike against divers due to the differing compressibility of gases, do not compound the problem by allowing gas temperatures to vary. Let the cylinder cool to ambient temperature between gas additions.

2) When diving the mix, watch your oxygen. If the oxygen fraction is too low at the surface, you may require a travel gas to get to a depth (pressure) where the PPO2 will sustain life. A minimum of 16 % oxygen is required to support life for a human being at rest. This is really only an issue with Heliair. Conversely, too hot of an oxygen mix (above a PPO2 of 1.6) may become toxic. This is very easy to do with Helitrox.

3) When mixing, ensure that the nitrox or air is introduced at a relatively quick rate to create enough turbulence to thoroughly mix the gases. Most blenders will fill to approximately eighty percent of the desired pressure, creating turbulent flow. Then let the cylinder cool to room temperature before very slowly (cool) filling to the final working pressure. An alternative is to let molecular migration take place by letting the mix stand overnight. If in doubt, tumble the tanks. Check for a homogeneous mix by analysing the oxygen at intervals until the result is constant. Once mixed, the gases will not separate.

Learning how to safely dive helium-based gas mixes is only half of the formula. The other half is the ability to consistently blend accurate mixes. With the right equipment and the knowledge, the equation is complete.

LEARN FROM PROFESSIONAL GAS BLENDERS, NO DIY STUFF!

Learn At Easy Divers Cyprus

Padi Gas Blender Course